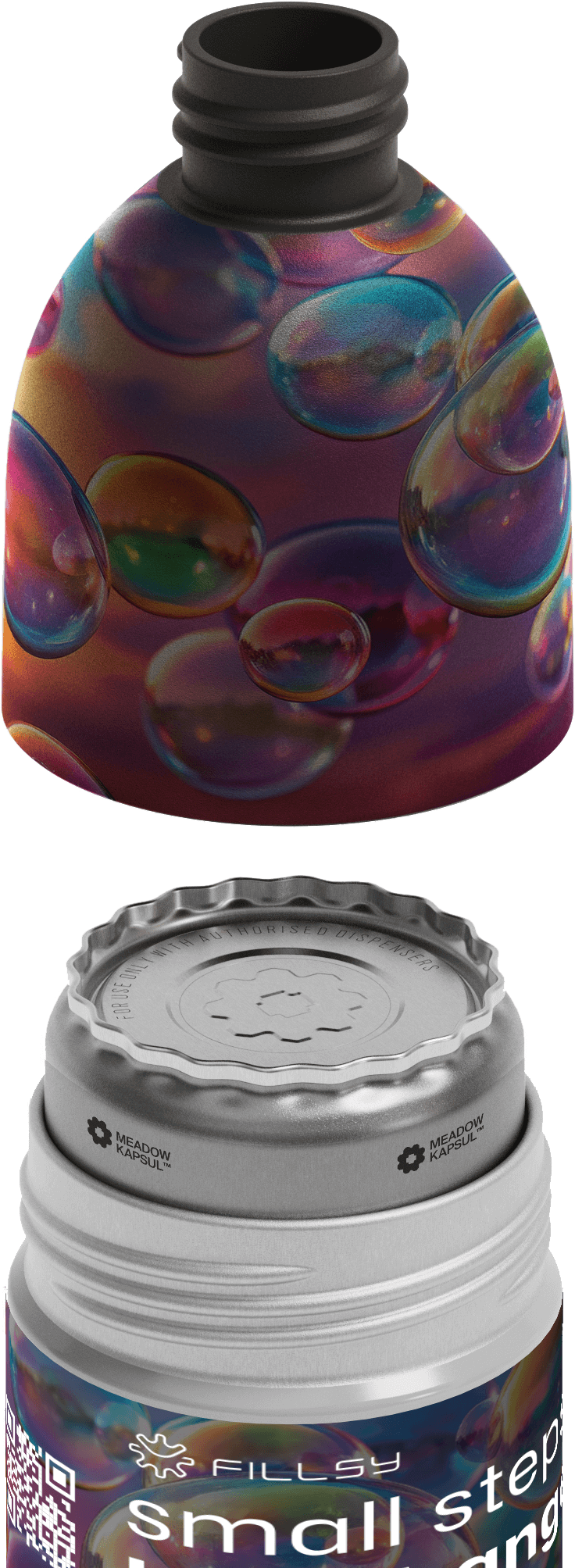

Pre-fill

Our pre-fill solution is ready-to-use – just like buying a new product. And once the can is empty, it’s recycled and back on the shelf in an average of 60 days. A simple, circular solution without the hassle of refilling.

Decide today on the best capacity for your products. Be innovative!

Offer your customers a modern and eco-friendly PRE-FILL system while meeting PPWR standards.

the same quality

in different variants

FILLSY

ONE | STOP

| SHOP

we’ll refer you to a proven R&D partner who will design a formula consistent with your briefing.

Our customer service department will take on the role of Project Manager.

We’ll find a manufacturer for you who will produce the product according to your formula.

If your product has not previously been packaged in aluminum cans, we will perform a PCT compatibility test. This is a necessary step to minimize the risk of incompatibility and ensure the product’s safety in contact with the packaging.

We will help you create a design for your chosen can capacity and verify its compliance with the technical production parameters of the packaging.

We will identify the best partner to deliver your cans. By purchasing through us, your chosen packaging may be cheaper!

We will fill your cans on a professional, high-capacity line, with full control over

We will prepare your cans for safe transport to your designated location. We will provide full documentation and logistics.

over 75%

aluminium

is still in circulation!

An aluminum can can be recycled almost infinitely, supporting a closed loop, reducing the use of natural resources, and reducing waste.

what’s on

Fillsy?

FILLSY and Meadow to Open New Sustainable Packaging Factory in Poland

The factory will help boost EU supply of recyclable packaging solutions, reaching a target capacity of 100 million cans per year by the end of 2027.

Polish co-packer FILLSY has today announced the opening of a manufacturing factory in Żyrardów, Poland, in partnership with Swedish packaging-tech company, Meadow. The factory will aid the production of Meadow’s infinitely recyclable aluminium pre-fill solution, The MEADOW KAPSUL™. The project is financed by FILLSY who will have invested €4 million by the end of 2027, with plans to invest a further €10 million to develop production lines and plant expansion by the end of 2030.

The announcement follows the EU’s adoption of the Packaging and Packaging Waste Regulation (PPWR) in February, in which European companies must meet binding targets for recyclability and material

reduction. The cutting-edge factory will play a key role in boosting the European region’s capacity to help meet growing industry demand for packaging solutions that are consumer-friendly, regulatory compliant

and help tackle the packaging waste crisis. Located in central Europe, Poland offers a strategically important base in terms of supply chain access and distribution, with major FMCG companies opening filling plants there in recent years, such as Unilever and L’Oréal.

FILLSY Co-Founder, Paweł Siwirski comments: “This factory marks a crucial step for the European packaging industry. By establishing this factory at the heart of Europe (in a country that is a growing hub for FMCG innovation), we are ensuring that the MEADOW KAPSUL™ system is readily available to brands across the continent. This investment is a huge step in strengthening Europe’s capacity to deliver sustainable packaging at scale, supporting the cosmetics and wider consumer goods industries as they work to comply with Packaging and packaging and waste regulation.”

With an output of up to 10 million units annually at this current time (and a target capacity of 100 million units per year by the end of 2027), the new facility will not only boost Meadow’s European production footprint, but also position FILLSY as the first European manufacturer to industrialise the MEADOW KAPSUL™ technology at scale. The factory will be equipped with state-of-the-art industrial machinery, designed to meet the demands of clients in the European market, as well as a dedicated showroom for MEADOW KAPSUL™. The showroom will provide partners and prospective clients with an opportunity to experience the technology first-hand and explore its applications across food, personal care and home product categories.

FILLSY joins a growing list of Meadow’s global partners, including the US’s largest producer of aluminium Ball Corporation, the largest global supplier of easy-open end system parts, DRT Holdings, and the global leader in aluminium recycling, Novelis.

Meadow CEO & Co-Founder, Victor Ljungberg comments: “We are thrilled to announce this partnership with FILLSY. It marks a major production foothold for Meadow in Europe, and comes at a time of growing market demand for our solutions. Collaboration is at the heart of our approach, and FILLSY is a crucial partner as we continue to grow and approach commercialisation.”

About Meadow

Founded in 2020, Meadow actualises the twin ambitions of reducing the impact of packaging waste while also enhancing consumer experience. It achieves this by repurposing the world’s cleanest metal – aluminium – into a pre-fill can that seeks to replace all single-use, linear packaging. Its innovative MEADOW KAPSUL™ technology offers a lightweight, user-friendly alternative to linear packaging across multiple industries, including personal care, beauty, food, and beverages. By harnessing aluminium’s infinite recyclability and partnering with global leaders like Ball Corporation, Meadow delivers scalable, sustainable packaging solutions that combine environmental impact reduction with enhanced consumer experience. Headquartered in Stockholm, Meadow is setting a new standard for circular packaging worldwide.

About FILLSY

FILLSY is the first company in Europe to mass produce Meadow’s MEADOW KAPSUL™ technology. FILLSY’s business mission is to provide one-stop-shop implementation services for this system. To this end, FILLSY has assembled a team of market experts who thoroughly understand the needs of the cosmetics market and properly manage the production process and the entire supply chain. Furthermore, FILLSY is an organization that places extreme importance on ecology. We operate according to the principle of “act in a way that does not harm the ecosystem.” We care for the planet and people. We demonstrate concern for the climate, but also for business relationships. We are motivated to work with our partners in a way that supports, not harms, business!

For Polish media enquires contact – Edyta Kresinska/ edyta.kresinska@fillsy.global/ +48 577 270 070

Learn about

our company

At FILLSY, we promote sustainable development. We actively create change in the innovation chain on the way to building a better future for future generations.

By changing the present, we build a better tomorrow!

The source of change, and more importantly, growth, are extraordinary meetings, simple solutions, and sometimes maturity and courage in decision-making are enough. Next comes our determination, hard work, and ultimately, a measurable impact on positive change in our immediate surroundings, and even the entire world! At FILLSY, we feel immense satisfaction in working to leave a lasting legacy for future generations.

We want to be like the local builders of the parish church in Żуrardów! Local residents, without any skills or additional incentives, formed a chain of human hands stretching several kilometers between the construction site and the brickyard in Radziejowice, passing bricks from hand to hand, carrying them to Żуrardów.

This and similar stories demonstrate how people can mobilize around clearly defined goals, ideas, and tasks. Determination and a sense of purpose are key factors influencing behavioral change for a better future. Similarly, we want to influence changes in social behavior and consumer habits, and promote business strategies that incorporate sustainability and an innovative approach to existing solutions, including packaging.

Promoting, and more importantly, implementing, ecological strategies is not only a time-sensitive requirement, but a short-term need and the foundation for all change. Our efforts are aimed at changing behavior at the consumer and business levels, using innovative solutions and comprehensively building awareness of how changing these behaviors will impact the future financially, environmentally, and for a better, healthier tomorrow.

Therefore, our goal is to have a positive impact every day – from our immediate surroundings to the global scale – demonstrating that small steps lead to big changes.

We are building a better tomorrow by making changes today!

SMALL STEPS, BIG CHANGE!

our

experts

Do you have any questions?

write to us!